Vereshchinsky A.P., Candidate of Technical Sciences, General Director of OLIS LLC

Music N.S.‚ process engineer, LLC “OLIS”

As is known, water-heat treatment (WHT) in flour milling is used to purposefully change the technological properties of grain in order to create optimal conditions for its processing into high-quality flour. As a result of HTO, the elasticity of the grain shells increases and the strength of the endosperm decreases, which ensures the effectiveness of subsequent selective grinding. Thus, the goal of varietal grinding is achieved: the crushed endosperm is extracted into flour, and the shells are sent to the bran. In addition, during WTO, the biochemical properties of grain and flour produced from it change: the ash content of flour decreases, the yield increases and the quality of gluten improves, and enzyme activity increases. Based on the significance of its influence on production results, WTO is the basis for preparing grain for varietal grinding.

According to the modern classification, which is based on the peculiarities of using the temperature factor in grain processing, a distinction is made between cold and hot conditioning methods. A comparative analysis of the technological efficiency of HTO methods shows that hot conditioning is somewhat more effective, but it is much more complicated to implement than cold conditioning, requires expensive hardware, and heating grain to a temperature of 50-70 °C is associated with significant energy costs.Currently, due to the listed features, hot conditioning methods are not used at domestic mills and, in conditions of global energy shortages, as well as its high cost, are losing their prospects.

However, cold air conditioning also has some significant disadvantages. The main problem of cold conditioning is the limited water absorption capacity of grain, which in some cases requires its moistening in several stages with intermediate dampening. The organization of multi-stage conditioning significantly increases the costs of creating and operating a grain WTO line. In addition, to ensure a technological effect during cold conditioning, long-term defoliation of grain is necessary, which requires bins of significant capacity. In accordance with current recommendations [1], the increase in moisture during one stage of moistening does not exceed 3.0-3.5%, and the total recommended dampening time can be more than 24 hours.

As a review of the literature shows, the disadvantages of cold conditioning are due to the peculiarities of the anatomical structure of the grain and the hygroscopic properties of its components. In the works of G.A. Egorova, E.D. Kazakova, L.N. Lyubarsky [2., 4.], as well as other domestic and foreign researchers, the mechanism of interaction of water with grain has been comprehensively and deeply studied. It has been established that upon contact with water, grain almost instantly absorbs 3-5% moisture, and only after 15-30 minutes does a further increase in its moisture content occur.This initial “capture” of water is carried out by the fruit shells of the grain, and is determined by the degree of development of their capillaries and pores.

Further dampening of the grain is associated with a significant inhibition of the penetration of moisture into the endosperm by the seed coats and aleurone layer. The seed coat, having a weakly expressed capillary system, is saturated with moisture much more slowly than the fruit coat and has a lower carrying capacity when it migrates inside the wheat grain. The aleurone layer is characterized by high hydrophilicity and water permeability, which is associated with a significant content of proteins in its cells. Due to the strong retention of water in the aleurone layer, endosperm hydration occurs with a delay of 0.5-1.0 hours.

Moistening of the endosperm is associated with its active loosening as a result of the formation of a network of microcracks. Loosening of the endosperm is the main influencing factor that improves the milling properties of grain as a result of HTO. This change is accompanied by swelling of the grains and a decrease in their glassiness. Data accumulated by science and practice show that the completion of the period of endosperm loosening, determined by the suspension of the above processes, corresponds to the acquisition of optimal flour-grinding properties by the grain. Moreover, the greater the increase in moisture and the higher the speed of its transfer, the greater the improvement in the milling properties of grain.

The work of L. N. Lyubarsky [4] proved the exceptional role of the embryo in grain moistening, which “pumps” water inside the grain using diffusion-osmotic forces. It is noted that grain moistening through the embryo occurs more intensively compared to moistening through the shell. In addition, under the action of enzymes of the embryo, a massive transfer of minerals occurs during the HTO process from the shells and aleurone layer to the endosperm, and then to the embryo. As a result of this transfer, the ash content of the shells, aleurone layer and endosperm decreases, and the embryo increases.

The analysis allows us to formulate a hypothesis about the possibility of intensifying the processes of cold grain conditioning by pre-husking it. An increase in the development of the active area of the fruit shell as a result of peeling should increase the water absorption capacity of the grain, and the targeted destruction of the integrity of the seed coat and aleurone layer should help increase the rate of moisture penetration into the endosperm. At the same time, it is known that mechanical impact on grain, such as peeling, can negatively affect its viability. Obviously, excessive damage to the embryo is a factor that limits the use of desquamation to intensify conditioning processes.

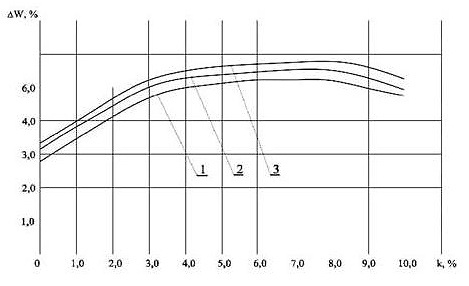

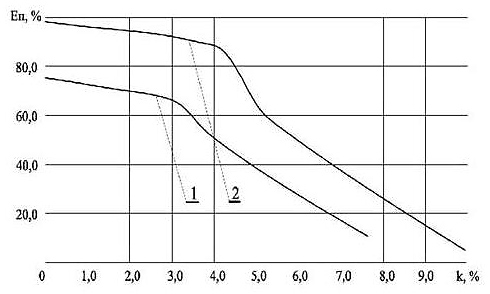

In order to test the hypothesis put forward, we conducted a series of laboratory studies to study the viability, water absorption capacity of grain, as well as the kinetics of its dehydration after processing with different peeling indices k. The study of the effect of grain peeling on grain viability was carried out by assessing its germination energy Ep, which was determined using standard methods. In Fig. Figure 1 shows graphs of the dependence of germination energy Ep on the hulling index k for wheat samples with different initial values of Ep.

Fig.1. Graphs of the dependence of germination energy Ep on the peeling index k.

Initial sample: 1 – Ep – = 75‚0%; 2 – Ep – = 98‚0%

From the analysis of the graphs (Fig. 1) it is clear that in the range of values k = 3-4%, there is a sharp decrease in the germination energy Ep. In this case, some grains are characterized by exposure of the internal organs of the embryo. A further increase in k values is associated with increased damage to the embryos, as well as the appearance of bare areas of endosperm on the surface of the grains. Examination of grains during germination shows that their bare surface areas contribute to the active development of mold fungi. Thus, a decrease in germination energy up to the complete loss of viability of hulled grains is associated with both mechanical damage to the embryos and the effects of mold. It should be noted that the vital activity of mold leads to changes in the specific properties of the protein complex of grain and, as a consequence. to a decrease in its nutritional value, deterioration in baking properties, and the formation of numerous mycotoxins, some of which are carcinogenic. In addition, it was noticed that grain processed at k values of more than 3-4%, when moistened and dampened, is prone to caking and sticking of grains with loss of flowability.

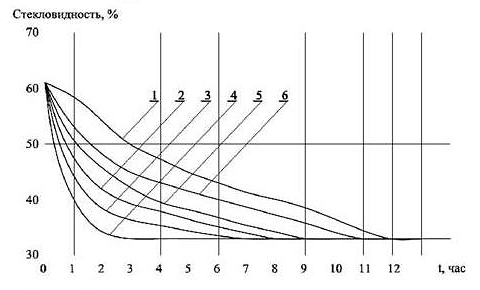

The water absorption capacity of grain was determined by directly immersing it in water using the following method [2]. The tested grain samples were immersed in water for different periods. After removal from water, the samples were immediately dried between sheets of filter paper, soaked separately for 24 hours in sealed containers, their moisture content was determined using a standard method, and the moisture increment ΔW was calculated. The results of these experiments are presented in Fig. 2.

Fig.2. Graphs of the dependence of the humidity increment ΔW on the peeling index k.

Original sample: W = 12.87%.

Water immersion time: 1 – 10 s; 2 – 20 s; 3 – 30 s.

The increment in moisture values determined for unhulled grain (ΔW = 3.0-3‚5%) is identical to the results obtained by researchers earlier and indicates that the recommended moisture increment for one stage of conditioning [1] is due to the maximum water absorption capacity of unhulled grain. Our data show that an increase in the peeling index k causes a significant increase in ΔW values, especially in the range k=0-3%. At the same time, at values of the peeling index k of more than 8%, a decrease in the grain moisture increment is observed.

Fig.3. Graph of changes in glassiness depending on the cooling time t:

1 – k=0%; 2 – k=1‚5%; 3 – k=3‚1%; 4 – k=5‚1%; 5 – k=7.4%; 6 – k=8‚9%

The kinetics of grain dehydration was studied by reducing its glassiness.Grain samples were moistened with the same moisture increment and chilled in an airtight container. After every hour of cooling, their glassiness was determined. In Fig. Figure 3 shows graphs of the dependence of the glassiness of the grain on the freezing time t for different values of k.

The results obtained allow us to establish that an increase in the peeling index k leads to a significant increase in the rate of grain dehulling. In this case, the maximum rate of dewetting is observed in the range of k = 5%. A further increase in the values of the peeling index k leads to a decrease in the rate of peeling.

The patterns presented in Fig. 2 and 3 confirm the validity of the hypothesis put forward. The features of the obtained dependencies are explained by changes in the structure of the surface layers of the grain, as well as the quantitative content of its anatomical parts with different hygroscopic properties, which is caused by the effect of peeling. In the range of values k=0-3%, an increase in water absorption capacity indicates an increase in the active area of the shells. However, maintaining the structure and quantitative content of the aleurone layer, which accumulates moisture, prevents the rate of grain dewetting from increasing to its maximum values. A further increase in k values is associated with the loss of a significant amount of fruit membranes by the grains and a decrease in the viability of the embryo, which should lead to a decrease in the water absorption capacity of the grain. However, the absence of the fruit shell and the violation of the integrity of the seed coat creates conditions for moisture to enter directly into the aleurone layer, which compensates for its “capture,” although in smaller increments. The maximum rate of dewetting, observed in the range of k=5%, is apparently due to the loss of most of the seed coat by the grains and the development of tears in the aleurone layer, which improves the penetration of moisture into the endosperm. A decrease in the specific content of the aleurone layer (at k values of more than 5%), which is characterized by high hygroscopicity and the ability to reliably retain absorbed moisture, leads to a decrease in the water absorption capacity of the grain and the rate of its dewetting. It is known that when hydrated, the gluten-forming endosperm proteins form the structure of the surface layer, characterized by reduced moisture permeability. In this regard, the endosperm, exposed as a result of peeling, is not able to quickly absorb a significant amount of moisture and reliably retain it.

The results of the conducted research allow us to formulate the following conclusions.

- Pre-husking of wheat significantly increases its water absorption capacity and the rate of moisture penetration into the endosperm.

- The preparation of grain by peeling for conditioning should be carried out without exposing the internal organs of the embryo and endosperm (k = 3-4%), which in most cases allows us to limit ourselves to one stage of HTO and ensure its technological efficiency with a significant reduction in the time of dehulling.

- Hulling of grain to k index values that ensure the maximum possible rate of moisture migration can be used after the first stage of conditioning in order to quickly adjust its results at the subsequent stage of conditioning.

- The widespread introduction into industry of the method of intensifying the WTO of grain by peeling it requires clarification, based on grinding practice, of the results presented and the development of appropriate modes, taking into account differences in the quality of grinding batches of grain entering processing.

Published based on materials

“Grain storage and processing”

scientific and practical journal

№6 (156) January 2012

LITERATURE

- Rules for organizing and maintaining the technological process at flour mills. – K.: Kiev Institute of Bread Products, 1998. – P. 17

- Egorov G.A. Technological properties of grain. – M.: Agropromizdat, 1985. – 333 p.

- Kazakov E.D. Hygroscopicity of grain components //Tr/MTIPP. – 1952. –S. 64-68.

- Lyubarsky L.N. Rye. – M.: Publishing House of Technical and Economic Literature, 1956. – 264 p.